Mach3 Serial Port Plugin Check

Question #: 13383 Question: how do I connect my spindle to mach3 so mach3 can control it Current Solution It is not necessary to connect the spindle VFD (Variable Frequency Drive also called an Inverter) to the computer or CNC motion electronics. The VFD can be controlled independently using the control panel on the VFD. The control panel has the ability to control all aspects of the spindle including Speed, Torque, limits, etc. However, you can connect the VFD to the computer so the CNC control program can control the spindle during the CNC Machine operation. You will need to connect the VFD to the computer via a serial conection (in this case, it is the RS-485 protocol).

Untuk materi belajar HTML dan CSS ini, sebelumnya sudah saya bagikan juga di website ini, yaitu belajar html dan belajar css (download ebook dasar html dan css dan tutorial css PDF lengkap dengan pengarang yang berbeda. Lalu Apa saja yang bisa Anda dapatkan dari ebook dengan judul “Mahir menguasai CSS, Tutorial dan Praktek”, berikut. CSS bukan merupakan bahasa pemograman. Pada kesempatan kali ini, seperti biasa untuk mengawali artikel pada kategori CSS sebelum membahas tutorial yang lain, saya akan berbagi ebook gratis untuk sobat angkringan tentang CSS, mungkin bermanfaat bagi para pemula yang ingin memahami CSS code ini. Ebook Css Bahasa Indonesia Lengkapan. Materi yang ada sangat lengkap untuk sebuah buku CSS pemula. Ebook css uncover sangat detail dalam menjelaskan materi css. Ebook css bahasa indonesia lengkap pengeluaran. Book Collection 2009 (HTML, CSS, Java. Script, PHP, Berikut ini merupakan daftar Proxy Tercepat di Indonesia: Download ebook css bahasa indonesia lengkap lagi mencari dan download Ebook Bahasa Pemrograman Lengkap Java, CSS, Javascript, HTML gratis dan tentunya ebook berbahasa indonesia.

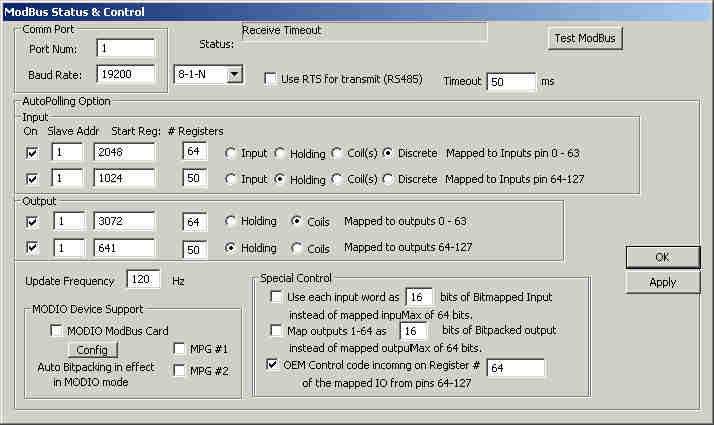

Then I checked the internal structure of the plugin and that's how i discovered that this. In principle, you should only have to change the COM port number in.

The following are instructions on how to connect the VFD to Mach3 via this RS-485 serial connection. The first thing you will need is the dynamic link library to pair with mach3 called the Huanyang VFD Mach3 PlugIn. Yes, you can control the speed of the 2.2 kW spindle, and the other spindles we sell, through Mach3 software. It requires making some changes to the settings in Mach3 and in your inverter. It also requires an additional part, which is called a USB to Serial Converter, found on our site here: I have some additional instructions, that I will send upon request, by email. I will also be adding a complete tutorial and video, to the website, on how to do this soon. Additional Information: 20 Click the link to respond: •.

The parallel breakout board has a relay that can turn the router on and off according to the control software in the computer. The router will turn on automatically prior to the machine moving (a time frame can be set so the router is up to speed). When the machine is finished and is not moving, the router automatically turns off. This is with the m3, m4, and m5 codes in the g-code. If you are interested in the USB breakout board, you will need to get an independent relay board.

Click the link to respond: •. It is not necessary to connect the spindle VFD (Variable Frequency Drive also called an Inverter) to the computer or CNC motion electronics. The VFD can be controlled independently using the control panel on the VFD. The control panel has the ability to control all aspects of the spindle including Speed, Torque, limits, etc. However, you can connect the VFD to the computer so the CNC control program can control the spindle during the CNC Machine operation. You will need to connect the VFD to the computer via a serial conection (in this case, it is the RS-485 protocol). The following are instructions on how to connect the VFD to Mach3 via this RS-485 serial connection.

The first thing you will need is the dynamic link library to pair with mach3 called the Huanyang VFD Mach3 PlugIn. It will depend on how you configure the machine to use the Laser and plasma. Is the laser on a separate gantry? That will determine the way you will connect the laser control system or if you use a typical CNC controller. The plasma will need inputs of THC on, THC up, THC down and outputs to trigger the plasma torch. I recommend the Pokeys57CNC for the plasma and you can also fire the laser with it, but you will not be able to do engraving with the laser unless you use a laser controller.

If you use a laser controller, you will need to either build circuitry to switch the digital signals from which controller you will be using, or if you have the laser on a separate gantry, you can use a traditional laser controller connected to the stepper motor drivers on that gantry. Users response: I was planing on using same gantry, and installing plasma and laser module on z axis along the side with current router. Perhaps if it’s needed installing another z axis on current z axis. So that when I use plasma, router z will be homed and plasma z axis will be able to utilize thc.

When you say “If you use a laser controller, you will need to either build circuitry to switch the digital signals from which controller you will be using,” If i install laser controller, pokeys and router motion card, do you mean all ( axis and router/laser/plasma) signals or just the one that controls router/laser/plasma? I was wondering if I could jump (parallel connect) axis signals from card to card without? Also do you prefer ethernet card or usb? I really do appreciate your help:) thanx again. Buildyourcnc response: Not a problem at all. 3d max keyboard shortcuts pdf download. Remember that with all of that weight on the z-axis, you will not be able to do efficient raster style engraving. By putting the laser on another gantry, say at the far end of the table, then you would be able to use a laser controller that controls its own stepper motors and the nozzle can have fast swing motion for engraving.